Workshop

WITHIN THIS PAGE:

(Search the Topics with the  label, for updates)

label, for updates)

BANJERS EQUIPMENT MANUFACTURERS' SITES AND INFORMATION

BANJERS EQUIPMENT MANUFACTURERS' SITES AND INFORMATION

(If you know some others, please tell us)

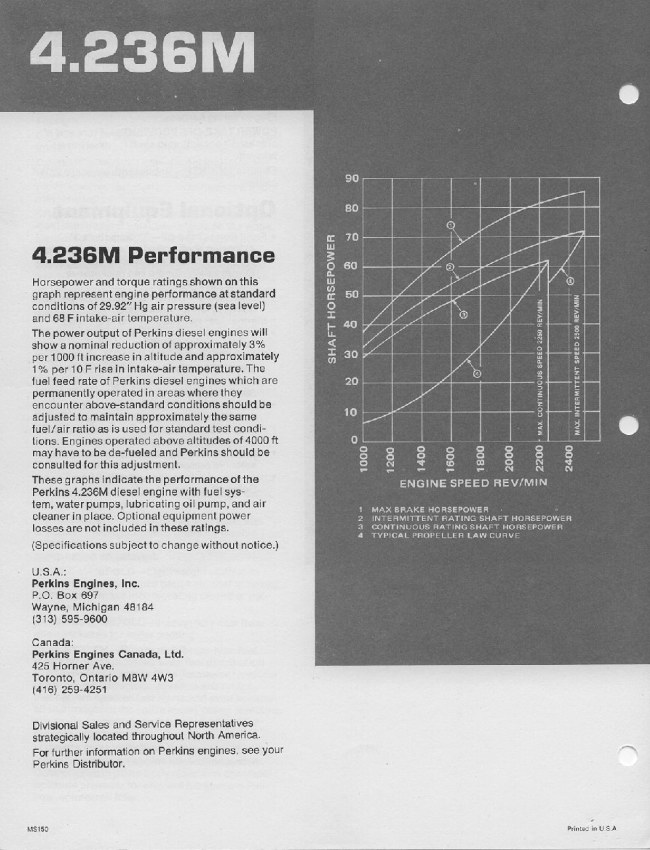

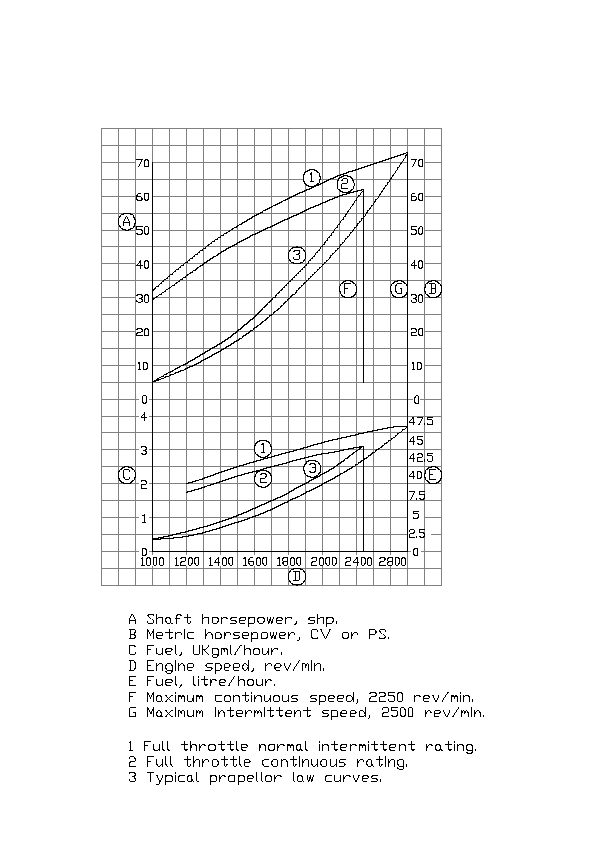

The engines originally mounted on the Banjer 37 were either Perkins 4-236M (62 BHP continuous) or Perkins T 6-354M, 95 BHP-6 cyl. version. Find more about Perkins-Sabre, world-wide distributors and services by clicking the name.

Perkins 4-236M series may go up to 85 HP SAE (63 kW or 86 metric HP).

Boatdiesel also has some useful calculators for Propellers, Power required ans Shafts, as well as engines specifations. You need to become a member to use this service.

Here you have the User's Handbook for Perkins 4236, from Oscar Alstede's pages (PDF format):

(Click on numbers to go)

You may also find a handbook for 4.212, 4.236 & 4.248 series at: http://motoren.ath.cx/ Search for Perkins in the left frame.

Perkins Parts (in the USA)

They even have On-Board cruise kits! :

Perkins 4-236 M

|

Perkins 6-354 M

|

|

|

|

08.11.2008

From our Honourable Treasurer, Ton Koot:

Dear friends,

A couple of years ago I spoke to Mr and Mrs Yates in a English harbour about Banjers and Perkins engines.

They gave me the addres of an (old) man who had bought all the Perkins spares. Must be much cheaper than via Perkins

This week I found the card with the adress.

Charlie Childs

500. Herne Road

Ramsey St. Mary

Ramsey

Nr. Peterborough

tel 01733-844362

Best Regards

Ton

09.11.2008

And our not less Honourable Secretary investigates:

I talked to Mr Childs - who is 78 - and he does have vast stocks of engines, blocks and parts. No website. No email. But his 24hrs a day fax number is 0044 (0) 1733 844769. This seems the best way to make contact!

Regards

Colin

Paragon Gearboxes

Paragon Gearboxes

Most Banjers mount Paragon 25L with Perkins 4236 and Paragon 35L with Perkins 6354. Reductions 3:1 both cases.

We thought Paragon Transmissions were not anymore in production, but Doug Frank, General Manager of Great Lakes Powers , the Original Equipment Manufacturer for the Paragon Marine Transmission, formerly The Paragon Gear Works of Tauton, Massachusetts, tells us: "We still continue to manufacture product for the Paragon units. We can still provide a complete unit depending on the model. We can provide for most units complete seal and gasket kits as well as clutch plates, bearings, brake bands, etc."

Contact data:

Great Lakes Powers

Customer Support Center Location:

7455 Tyler Boulevard

Mentor, Ohio 44060

Phone:

(440) 951-5111

(800) 325-6880

(888) 340-4457

Fax:

(440) 953-1052

Email:

|

Product request.

The order of personnel that you should e-mail are:

Charlie Rother - crother@glpower.com

Chuck Hancock - chancock@glpower.com

Jeff Gallagher - jgallagher@glpower.com

|

Marine and Industrial Transmissions Ltd

Queenborough Shipyard

Queenborough

Kent ME11 5AL

T. 0044 1795 580808

It is said that in Canada you can find a good inventory of Paragon parts at:

Marisol Marine Centre,

1637 Columbia Street,

NORTH VANCOUVER

V7J 1A5 British Columbia

Telephone: +1 604 986-5291

In Holland you've got::

Representative (Parts)

|

Workshop (Repairs)

|

KEMPER EN VAN TWIST DIESEL

Mijlweg 33

3316 BE Dordrecht

Fax: 078-6136746

Tel: 078-6326600

|

Drinkwaard Motoren B.V.

Baanhoek 152 - Postbus 265

3360 AG - Sliedrecht

Telefoon +31(0)184-412332

Fax +31(0)184-499925

info@drinkwaard.com

|

Bob & Jenny, from banjer NAÏK, told us the following:

Bob & Jenny, from banjer NAÏK, told us the following:

"We changed the gearbox in Nieuw Amsterdam

There is a man there that has every spare part you need for the paragon gearboxes

He has also new ones and he knows every thing about paragon

He has a workshop in his garden with everything you can imagen concerning paragon gearboxes, new and overhauled"

Scheper Scheepsreparateur W

Vaart ZZ 81

7833AD

Nieuw-Amsterdam

0591-551881

We are searching for more World wide marine parts companies also working Paragon. If you know one, let us know.

Possible alternative gearboxes for your Paragon P25 (Mounted with Perkins 4236).

(Some BMC members had to replace gearboxes, and found no Paragons available at their countries)

Trade mark

|

Model

|

Ratio

|

Maximum HP

at 2250 rpm

|

Newage

|

PRM 260

|

2.94:1

|

82

|

Twin Disc Technodrive

|

TM 93

|

2.77:1

|

108

|

Twin Disc

|

MG-5012 SC

|

2.77:1

|

109

|

ZF Marine

|

ZF 45-1

|

3.03:1

|

142

|

You should adjust the pitch of your propeller to suit new gearbox.

Consult a reputable mechanical engineer and a propellers expert,

before attempting a transmission gear change over.

26.02.05

Our fellowmember Dees contacted PARAGON's headquarters in USA and asked them the question of letting or not your propeller to freewheel (As to avoid gear damage). Here the answer from Charles Rother of Great Lakes Power Products:

"IT DOES NOT DAMAGE THE TRANSMISSION TO HAVE THE PROPELLER FREEWHEEL. JUST AS

A PRECAUTION, AND YOU PROBABLY DO THIS ANYWAY, THE TRANSMISSION SHOULD BE SHIFTED

INTO NEUTRAL BEFORE THE ENGINE IS SHUT DOWN".

27.07.05 Paragon Engineering, from Great Lakes Power Products inform us:

"The Paragon P25L has tapered roller bearings at the output shaft to accept propeller thrust. The maximum gasoline pleasure craft rating of the P25L is 220 HP at 4000 RPM. The output bearings were selected to handle the propeller thrust produced by this maximum application. The thrust produced by this Banjer 37 application can be adequately handled by the tapered roller bearings in the Paragon P25L transmission".

So, folks which's Banjer mounts this gearbox (And most probably the Paragon 35 also): The shaft bearing located at the rear bulkhead of your Banjers is of no use, and you'd better remove it, in my humble opinion, because can cause alignation, vibrations and heating problems in the shaft.

Guillermo.

22.08.05 Raw water Oil Coolers for Paragon 25L not longer available from manufacturer

I've received this message from PARAGON, regarding my inquiry for a replacenet for the P25L Oil Cooler (Which works with raw water):

"DEAR MR. GEFAELL,

OIL COOLER, P/N 11829, WAS GENERALLY RECOMMENDED FOR THE 200 SERIESTRANSMISSIONS ESPECIALLY IN PLEASURE BOAT APPLICATION. THIS COOLER HAS A NOMINAL SIZE OF 2 X 5 INCHES.

AT THIS TIME, WE ARE NO LONGER STOCKING P/N 11829 AND ARE RECOMMENDING P/N 11914. THIS COOLER HAS A NOMINAL SIZE OF 2 X 6 INCHES. EITHER OF THESE COOLERS WOULD HAVE COPPER WATER PASSAGE TUBING MEANING THAT THEY ARE FOR USE IN A CLOSED COOLING SYSTEM (FRESH WATER) ONLY. WE DO NOT OFFER A COOLER FOR USE WITH RAW (SALT) WATER. THE P/N 11914 COOLER IS CURRENTLY AVAILABLE FROM OUR STOCK AT 111.08 USD

PLUS SHIPPING.

WE DO NOT HAVE A REPRESENTATIVE IN SPAIN. FOR MOST EUROPEAN INQUIRIES, WE RECOMMEND OUR MASTER DISTRIBUTOR IN THE NETHERLANDS, KEMPER EN VAN TWIST DIESEL BV. THEY CAN BE FOUND ON THE INTERNET AT: //www.kvt.nl/ THEIR PARTS MANAGER IS JACK WEIJTS. IT IS POSSIBLE THAT KEMPER MIGHT HAVE OTHER OPTIONS AVAILABLE FOR YOU.

IF ANY QUSTIONS, PLEASE DIRECT THEM TO US ANY TIME. THANK YOU FOR YOUR INQUIRY AND INTEREST.

KIND REGARDS,

CHARLES ROTHER

GREAT LAKES POWER PRODUCTS

EMAIL: crother@glpower.com

June 09, 2009

Steve Bennets (KERENSA) send us this useful information on Paragon 25L working pressure:

NORMAL OPERATING OIL PRESSURE AT ENGINE SPEEDS ABOVE 1000 RPM IS 120 PSI ASSUMING THE TRANSMISSION IS IN GOOD CONDITION. AT 60 PSI THE

TRANSMISSION SHOULD DO LITTLE TO NOTHING AS THE PRESSURE RELIEF VALVE IS SET UP FOR APPROXIMATELY 85 PSI. MOST SMALL TUBE AND SHELL

COOLERS ARE PRESSURE TESTED BY THEIR MANUFACTURER AT 200 PSI FOR THE TUBES AND 250 PSI FOR THE SHELL.

OUR DISTRIBUTOR IN THE UK IS MARINE AND INDUSTRIAL TRANSMISSION

SERVICE AT www.mitgroup.co.uk OR TEL. 1795 580808

THEIR SERVICE MANAGER IS p.edy@mitgroup.co.uk

THANK YOU AND REGARDS,

CHARLIE ROTHER

Great Lakes Power Products

SEFFLE MOTORVEKSTAD

This firm in Sweden, seeming not anymore at work, was the manufacturer of the steering system. This system is type HL4, Manufacturing number 333. Interested fellowmembers can get a copy of the original booklet about this system, from Guillermo.

Our fellow member Maarten tells us that PROMAC used to serve the Seffle steering gear in Holland and abroad.

13.07.05: Colin Whimster informs about a press release confirming that the trade of Sheffle has been taken over by Promac.

Promac B.V.

Van Voordenpark 14

5301 KP Zaltbommel

The Netherlands

Postal address P.O. Box 22

5300 AA Zaltbommel

The Netherlands

Contact Mr. Gert Jan van der Gaag

Phone + 31 (0)418-68 33 33

Fax + 31 (0)418-68 33 55

Promac Agents in the UK

Martin Saer

Euromarine Ltd

++44 238 058 0020

April 20, 2008

DAMY III's owner informs us about the kneecaps of the steering system able to be replaced using automotive parts:

"Voici enfin les références de ROTULES qui s'adaptent parfaitement à la direction hydraulique du BANJER

Manufacturer: SIDEM

OE Ref : 811 419 812

Batchnr : P 064286

pour vehicules (Audi 80/VW Derby - Passat - Polo - Santana)

- Le Filetage (thread) et le cône s'adaptent parfaitement aux vérins et supports

Adresse du fabricant:

info@sidem.be

Amitiés bonjour à tous DAMY 3 "

Sept 25, 2008

Hello Guillermo,

I want to tell you that we have renamed ANNE MARIE to TIJDVERDRIJF.

Promac could not fix my Seffle steering gear (they are very helpful), so I replaced by a Vetus MTC175 and pump HTP4210r and working both excellent, I think 2 turn less .

regards Hans Ekdom.

PORTHOLES AND WINDOWS

One of the original manufacturers for Banjers' portholes and wheelhouse windows is still at work. You can find they page by clicking the name upwards.

RAFA

Ambachyweg 28

3831 KB Leusden

Nederland

t. 033 4945040

25.05.2008

PANDORA inform us from Cyprus about the GEBO manufacturer, who also produces portholes and windows for the Banjers.

04/04/2016

DAVID MERLOT, from France, tells us he has been more than 40 years working for WAUQUIEZ SHIPYARD and did a complet restoration of the portholes on a BANJER 37 based near Marseille, France. The portholes are made in Italy. Contact: davidmerlot@orange.fr

OTHER EQUIPMENT

International Steel Supplies Inc. is the original firm, at 's-Hertogenbosch, NL, where most of the stainless steel parts of Banjers were made. They are still at work but seem to be oriented nowadays towards industrial markets, rather than boating.

Banjers mounted a Blake-Lavac-Taylors paraffin cooker with oven and many even mounted also Taylors paraffin heaters. Here you have their home.

The original compasses for Banjers were Silva, made in Sweden. They are still leading you into proper course...

Banjers Fresh Water Pressure System included an electrical diaphragm pump from Jabsco.

The heads were from Raritan. You'll still can find parts from them for the old models.

You still can find spare parts for the two original Whale Gusher 25 bilge pumps here (Although not cheap at all...!)

Some of the Banjers still keep on board the original Vaillant Geyser gas water heater. Here you have the manufacturer's site, still alive and kicking since 1924, but unluckily not producing that old model anymore. I think Banjers mounted any of these models: the MAG 125, the MAG 250 or the MAG 325. There were several versions of those, depending on the gas to be burnt. Here some spare parts for the MAG 125: http://www.leisureshopdirect.com/Caravan/gas/Vaillant_water_heater.aspx

Note: Gas water heaters are not any more allowed for cabin installation, under the CE Recreational Craft Directive.

The first VHF sets mounted on board Banjers were those rugged and reliable Sailor radios with a dialing channel selector.

The Banjers' decks were covered with this excellent diamond-pattern anti-slip product.

Air heaters were optional in Banjers, made by this UK company.

Original locks, door hingues, etc, etc, for Banjers. Still producing the same models! (In Dutch)

(Information kindly provided by Frank de Visser and Ineke de Grijs.)

Simpson Lawrence Windlass

Simpson Lawrence Windlass

Our Honourable Secretary, Colin Whimster, informs us on the original windlasses:

"When Simpson Lawrence of Glasgow went out of business some products were taken over by Lewmar but someone who had worked at SL bought a lot of the spares. He is John McMaster and he lives near Glasgow.

ANCHORING

ANCHORING

Rules to choose the Anchoring Tackle has been, till recent times, a matter of experience and sometimes even a matter of wisdom and wishful tinking.

Rules and Regulations of the several Classification Societies allowed (and still do) for simple formulae to choose a ships' tackle, based mainly in Britany style anchors and all chain rodes. As those are empirical, based on many ship's tests, thousand of feedbacks from the industry, and only consider good mud and sand bottoms as those found in the charts' anchoring spots, results are quite similar from one Society to the other. Nowadays engineers have powerful and precise calculating methods, used to design case to case permanent anchoring tackles for big floating structures as oil rigs, etc.

Working and fishing boats usually do not anchor, simply because they do not need to, excepting in specific situations not highly demanding. So anchoring is an skill not mastered at all by most of the professionals in these fields. All fishermen I know through my professional activity only know and use the local variation of the grapnel anchor, good only for rocky bottoms.

Yatching is probably the most demanding field for anchoring techniques and equipment, because of the variety of bottoms, weather and other anchoring spots conditions. But until recent times it was based on simple 'rule of thumb' or semi-scientific methods.

The better approach for anchors manufacturers/developers was to do several anchoring tests, results varying significantly from one manufacturer to the other, because they were made under different conditions: Bottom quality, depth, rode composition and length, etc., were not uniform, and manufactures having not standarized published data to compare their results with others'. So the only way of comparing was to perform their own testing against competition units. And some manufactures tend to 'bend' reality towards their interests and hide to the public the negative aspects of their anchors. Unluckily this still applies in many cases....

A more scientific approach is taken nowadays by designers, as well as several independent studies have being performed. But again the not standarized tests conditions make it difficult to obtain general conclusions, although well stablished myths are falling quickly down. Many owners still doubt, feel confused or believe they do not have enough knowledge when choosing their anchoring tackle, being to them the best source of information the feedback from the cruising community, through Forums, etc.

Just to try to help fellowmembers of the Banjer 37 Motorsailer Club to better choose their equipment or judge the existing one, I'll navigate through all (to me) available information, post it here, analize it, and then, with the help of other experienced members, try to arrive to some conclusions and recomendations to be used in our beloved Banjers. I'd very much appreciate all contributions.

Guillermo.

First let's have a look about what has to be taken in account when designing an anchor. I find these pages useful to this end.

From the pages of the Dutch firm Vryhof Ankers, specialized in big anchors for the offshore industry.

"We are all aware that real-world anchoring is more complex than an idealized mathematical model or lab test..."

"An anchor rode is not an straight link between the bow and the anchor..."

Includes an useful Anchor Catenary Calculator.

Now, we'll have a look to several anchors tests available in internet:

"Of the anchors tested, only five passed the threshold of 1,000 lbs. and only four could arguably pass as storm anchors. The holding power of those four exceeded storm anchor requirements, but failed to do so on a consistent basis."

AVERAGE HOLDING POWER (SAND)

FX 37

|

3,263 lbs.

|

Performance 35

|

1,724 lbs.

|

CQR 45

|

1,304 lbs.

|

MAX 17

|

1,268 lbs.

|

Delta 35

|

801 lbs.

|

Bruce 44

|

496 lbs.

|

"It would seem preferable for an anchor to not set than to set and hold at only moderate conditions"

"Anchors which come highly recommended, even those which are successful in the marketplace, may not perform in the real world."

"These tests were conducted in order to establish a reliable, controlled database for comparing the performance of various popular recreational marine anchors in soft muddy sea floor conditions."

Here you have their results:

TYPE

|

WEIGHT

Lbs.

|

AVG.

DEPTH

|

MAX

PULL

|

AVG

PULL

|

MIN

PULL

|

SLACK

LINES

|

HP/LB

|

Bruce 44

|

46

|

25.4

|

300

|

280

|

250

|

0

|

6.1

|

CQR 45

|

47

|

22.2

|

525

|

440

|

400

|

4

|

9.4

|

Delta 35

|

33

|

24.8

|

625

|

502

|

200

|

4

|

15.2

|

H-1800

|

33

|

24.4

|

825

|

725

|

325

|

4

|

22.0

|

T-4000

|

30

|

23.0

|

1050

|

725

|

450

|

0

|

24.2

|

FX-37 32 deg.

|

20

|

22.5

|

1325

|

825

|

675

|

2

|

41.3

|

FX-37 45 deg.

|

20

|

24.8

|

2500

|

2175

|

2000

|

0

|

108.8

|

VSB-3600

|

28

|

24.6

|

|

1315

|

1150

|

2

|

47

|

WILD CARD GROUP

|

|

|

|

|

|

|

|

FX-85 32 deg.

|

44

|

21.3

|

1400

|

1200

|

850

|

0

|

27.3

|

FX-85 45 deg.

|

44

|

20.7

|

5150

|

4716

|

4300

|

1

|

107.2

|

FX-125 32 deg.

|

65

|

21.3

|

2500

|

2283

|

2150

|

0

|

35.1

|

FX-125 45 deg.

|

65

|

21.7

|

6600

|

6166

|

5400

|

1

|

94.9

|

From this Test Series, we can conclude that for soft mud bottoms, we should use devotedly designed anchors, as the Fortress FX, set at 45º. They have holding power/weight ratios around 100, which is outstanding.

On the other hand it seems to be clear that plow type anchors, as CQR, Bruce, Delta and the like, are not good for soft mud bottoms.

"All of the manufacturers of these anchors recomend them for boats between 33 and 38 feet in length..."

Test Series performed by the manufacturers of the Super Max anchor, not being enough accurate, in my opinion, due to the low number of tests performed and not rigurous enough method.

From the pages of Fortress anchors.

"If you, like me, enjoy anchoring in those small, remote coves, you are sure to have dragged your anchor at some time : no matter what anchor you use, poor holding or strong winds will have made sure of that." (Alain Poiraud). Interesting tets series, where the setting ability of anchors on sandy bottoms was observed. Very interesting conclusions on instability of Flat Anchors.

Comprehensive test performed by "When direction is reversed 140º. a third of the anchors never broke out, another third reset at some length, and two never reset".

Finding a mud site was not easy....

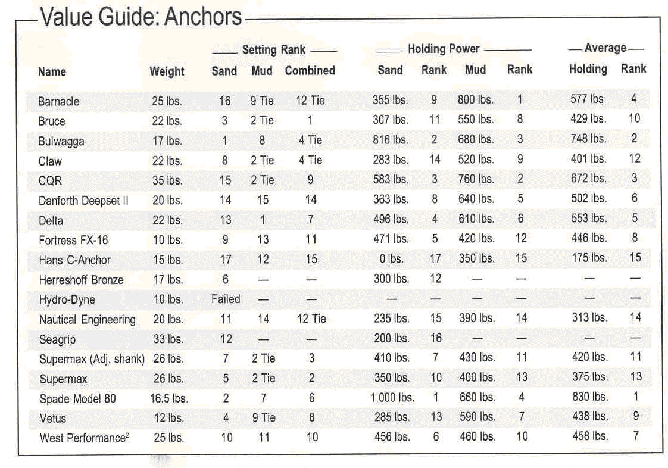

Value guide table from Practical Sailor's tests

Well, having read down to here through all of the previous Tests reports, I feel somewhat confused. Anyhow I tend to trust the tests marked  . To try to help fellowmembers of the Banjer 37 Motorsailer Club to make their own decissions on what anchoring tackle(s) should be better for Banjers use, I'll try to arrive to some conclusions, based on my own experience and knowledge, as well as on most welcome expected contributions from BMC members and friends.

. To try to help fellowmembers of the Banjer 37 Motorsailer Club to make their own decissions on what anchoring tackle(s) should be better for Banjers use, I'll try to arrive to some conclusions, based on my own experience and knowledge, as well as on most welcome expected contributions from BMC members and friends.

Some other interesting pages related to anchoring:

"The main and ONLY advantage of the chain is that it is the only and perfect mean to avoid chafing of the anchoring rode on agressive sea beds. Except for this point, chain has all the disadvantages..."

"If the chain splice is examined for chafe on a regular basis, we find no objections to the rope to chain splice from a strength reduction standpoint, as it appears close in strength to other components in the system and to commonly available nylon line."

Now, let's go on working on what is needed for Banjer sized boats:

CALCULATED ANCHOR CABLE TENSION IN WIND AND WAVES, FOR 36' KETCHS

The following table is based on Bob Smith's analysis of the force applied to sailboats of different sizes in wind and waves based on observations in the Columbia River. Correction factor of 1.25 applied for ketch rig. (Excerpted from The Sailing Foundation Anchor Tests)

WIND VELOCITY (KNOTS)

|

|

21

|

24

|

27

|

30

|

33

|

36

|

39

|

42

|

45

|

48

|

51

|

54

|

57

|

60

|

63

|

RODE TENSION (LBS)

|

|

169

|

220

|

280

|

345

|

417

|

496

|

581

|

675

|

774

|

881

|

995

|

1116

|

1244

|

1352

|

1520

|

RODE TENSION (KGF)

|

|

77

|

100

|

127

|

156

|

189

|

225

|

264

|

306

|

351

|

400

|

451

|

506

|

564

|

613

|

689

|

(Rode scope of five times depth. Boat veered 30 degree to wind)

Notice that with a 63 knots wind (Superior limit for Force 11) the rode tension (equal to wind & waves force) acting on the theoretical typical 36' ketch, is only slightly less than the Bollard Pull estimated downwards in this page for a 27" diameter propeller (746 kg) in Banjers with the Perkins 4236. This means that even with full engine throttle, a Banjer would not be able to make a headway. In real life this is even worse at sea, because waves are really much bigger than those found when the Columbia River test, where fetch was (most probably) relatively short.

The Beaufort Scale

|

Light Air

|

Light Breeze

|

Gentle Breeze

|

Mod. Breeze

|

Fresh Breeze

|

Strong Breeze

|

Force

|

1

|

2

|

3

|

4

|

5

|

6

|

Knots

|

1-3

|

4-6

|

7-10

|

11-16

|

17-21

|

22-27

|

|

|

|

|

|

|

|

|

Near Gale

|

Gale

|

Strong Gale

|

Storm

|

Violent Storm

|

Hurricane

|

Force

|

7

|

8

|

9

|

10

|

11

|

12

|

Knots

|

28-33

|

34-40

|

41-47

|

48-55

|

56-63

|

64+

|

The worst time for an anchor to drag is in extreme conditions. Those situations often occur at night, on lee shores or when a vessel may be surrounded by coral heads, breakers or other boats. So we have to calculate our anchor for the worst expectable conditions, let's say the top of Force 11, 63 knots winds, as we have to put a reasonable limit, unless wanting to carry something like an oil rig's anchoring system aboard.

The tests we've seen upwards here, indicate that because most anchors do not perform well in rocky, kelp/weed-infested areas, a selection of suitability of bottom for anchoring, may be more important than selection of an anchor. Indications on nautical charts of bottom characteristics are very general. Investigation of holding ground is possible through experience and, if all else fails, experimentation. Since it is generally difficult to verify the quality of the set, the best insurance is personal experience with a given anchor design and its suitability for specific bottom conditions.

We know now what kind of forces our grounding tackle has to withstand. Now, how can we calculate what is needed for our Banjers?

I'll try to follow some recommended methods, commonly used by the boating and shipping community. But first we may have a look at the web sites linked inmediately down here, as I find they are helpful stuff to simply calculate the anchoring tackle, as well as having very interesting info.

Detailed information from the manufacturers of the Flook anchor. Although rigurous, is easy to follow. Includes an useful nomogram, the 'Anchor Computer'.

(Click on image to find it in Dunhulty's pages)

From Al's Software Sailing Page. Most useful. Most probably all you need to know about anchoring calculations, although some simple maths are required. You may download from there several useful spreadsheets, allowing you to simulate your rode configuration. Down here you'll find a link to download his Synthetic Formulae spreadsheet.

Al's Anchoring Tackle Calculator

(Click on anchor image to download it directly to your computer)

26.10.2005

At the Safe Anchoring Guide web page from Fortress anchors' web site, they provide a table to determine the holding power needed as a function of wind velocity and boat length, for average beam and windage boats:

WIND

SPEED

|

BOAT LENGTH in FEET. Holding in pounds

|

20ft

|

25ft

|

30ft

|

35ft

|

40ft

|

50ft

|

60ft

|

70ft

|

15 kts

|

90

|

125

|

175

|

225

|

300

|

400

|

500

|

675

|

30 kts

|

360

|

490

|

700

|

900

|

1,200

|

1,600

|

2,000

|

2,700

|

42 kts

|

720

|

980

|

1,400

|

1,800

|

2,400

|

3,200

|

4,000

|

5,400

|

60 kts

|

1,440

|

1,960

|

2,800

|

3,600

|

4,800

|

6,400

|

8,000

|

10,800

|

WIND

SPEED

|

BOAT LENGTH in METERS. Holding in kg

|

6m

|

8m

|

9m

|

11m

|

12m

|

15m

|

18m

|

21m

|

15 kts

|

41

|

57

|

79

|

102

|

136

|

181

|

227

|

306

|

30 kts

|

163

|

222

|

318

|

408

|

544

|

726

|

907

|

1,225

|

42 kts

|

327

|

445

|

635

|

816

|

1,089

|

1,452

|

1,814

|

2,449

|

60 kts

|

653

|

889

|

1,270

|

1,633

|

2,177

|

2,903

|

3,629

|

4,899

|

They also state the following: A “Lunch Hook” should be able to hold your boat in a 15 kn breeze. A main, or “Working Anchor” should hold up to 30 knots of wind. A “Storm Anchor” is for winds up to 42 knots.

And now let's put to work.

BANJER'S GROUND TACKLE ESTIMATION (Several Methods)

1.- Following different Rules and methods.

1.1.- Spain/CE

First let's use one of the possible recomended tables to choose an anchor and it's rode that are available around there. In Spain we have a compulsory regulation for the recreative market, based in CE's rules & regulations, as follows:

Anchor and Rode chooser, under the Spanish Rules & Regulations

Boat hull length Anchor weight Chain diameter (*) Rope diameter (nylon)

Anchor weight is supposed for what Spanish authorities assume as to being high holding power anchors

(CQR, Delta, Bruce, etc., and the like).

Chain shall be at least equal to one boat length long, and total rode at least 5 boat lengths long.

(*) Galvanized steel, under EN 24565

So, allowing for some margin, let's say that for a 36 footer, like Banjers, we should use, as a minimum, a 20 kg high holding power anchor, with 12 m of 8 mm chain and 48 m of 12 mm nylon rope. From here you can go up to the sizes your experience (or fear!) dictates.

1.2.- USA

Now the recomendations from the ABYC (American Boat and Yacht Council). The table express the recommended holding power in pounds. From the pages of BoatUS, where you'll find more useful info about anchoring.

Boat Dimensions Horizontal Load (lbs.)

|

Length

|

Beam (Power)

|

Beam (Sail )

|

Lunch Hook

|

Working Anchor

|

Storm Anchor

|

10’

|

5’

|

4’

|

40

|

160

|

320

|

15’

|

6’

|

5’

|

60

|

250

|

500

|

20’

|

8’

|

7’

|

90

|

360

|

720

|

25’

|

9’

|

8’

|

125

|

490

|

980

|

30'

|

11'

|

9'

|

175

|

700

|

1,400

|

35'

|

13'

|

10'

|

225

|

900

|

1,800

|

40'

|

14'

|

11'

|

300

|

1,200

|

2,400

|

50'

|

16'

|

13'

|

400

|

1,600

|

3,200

|

60'

|

18'

|

15'

|

500

|

2,000

|

4,000

|

So, for our beloved Banjers, we shoud use something slightly bigger than found in the bolded line. Let's say:

Lunch Hook: 240 lbs (109 kgf); Working anchor: 960 lbs (436 kgf); Storm Anchor: 1920 lbs (871 kgf)

Comparing this with the upper Bob Smith's analysis, where 1520 lbs were calculated for a 63 knots wind, indicates the ABYC seems to be somewhat conservative, as I've also read about at some cruising forums. But, at sea, to be conservative increases your security and, on the other hand, I'm not so sure about Bob's data interpretation, as well as not knowing the wind force used by ABYC for Storm conditions.

On the rode side, Boat US recommends a lenght of 300' (91.4m) of 3-strand 1/2" (12.7 mm) Nylon, and 3/8" (9,5 mm) chain for a 35 footer, so in our case we can asume:

Rode: Length, roughly 100 m; 13 mm Nylon rope; 9.8 mm chain

Chapman’s suggests using one half foot of chain for each foot of boat length, so in our case 4.75 m. But Earl Hinz, a former aeronautical engineer and inveterate Pacific Ocean sailor, in his work The Complete Book of Anchoring and Mooring, says “the chain lead should weigh at least as much as the anchor whose weight it is supplementing”. From his experience, he has determined that the length of the chain lead has nothing to do with the depth of the water or the length of the boat. His suggested formulae:

Minimum Chain Length = (Anchor weight in lbs * Anchor material factor) / Unit weight of chain in lbs/ft

Anchor material factor = 1 for steel and 1.6 for aluminium

For a 20 kg (43 lbs) steel anchor and a 8 mm chain (weighing 1.15 lbs per foot), as those recommended in the Spanish regulation, we should use 11.4 m (37.4 feet) of chain, more or less one boat length for Banjers. The Spanish chain's length reccomendation seems to be quite adequate, according to this, but asks for a too short total rode length, according to Boat US. I believe Spanish authorities are taking in account the almost universal recommendation of letting out a rode length of about 5 times the depth, for "standard" anchoring.

1.3.- The traditional method.

Among the cruising community there is a simple rule many folks used to talk about: "You need a main anchor weighing 1 pound per waterline foot". So, for Banjers with a waterline length of about 31.17 feet, we shoud go for a 32 lbs anchor. I find this number not really enough at all for Banjers, as my own 'working tackle' with a 33 lbs Admiralty anchor has proven inadequate on sandy bottoms with strong winds in the range of Force 6. Confirming this, numbers obtained with the calculator mentioned in point 4, suggest that my working tackle will not withstand winds in excess of 20 knots (Force 5).

1.4.- Calculations using Al's Anchoring Tackle Calculator.

We enter Al's calculator with the following data, taken from my own good old MARIE:

11.13 m boat length, 10 mm chain diameter, 50 m available chain length, 63 knots wind speed, 800 daN selected rode tension, 6.5 m total depth (5 water + 1.5 freeboard), Medium seabed holding. (Note: 1 daN = 10 N = 10/9.81 kgf = 1.02 kgf)

Results:

a) All chain rode: 3.5º rode angulation at anchor. 8:1 scope, 21 kg minimum anchor weight.

b) Mixed rode for a 0º angulation: 20 kg anchor, 50 m chain, 22 m nylon rope.

Notes:

Static mode tension for 63 knots appears at the calculator to be 650 daN (663kgf), which coincides pretty well with the upper Bob Smyths analysis (689 kgf), although data there is said to include waves effect (?). Dynamic overtension with mixed rode goes in Al's calculator up to 1430 daN, and with all chain rode staggers to an incredible 3251 daN.

The data taken from MARIE, with a 20 kg CQR, 50 m chain, and the adition of 22 m of nylon rope, as well as using the 800 kgf rode tension, indicates that the boat is able to withstand winds of 47 knots, the upper limit of a Force 9, with a 0º rode angulation at the anchor, which is more than enough for my usual sailings.

If we calculate with 1430 daN, we arrive to the needing of a 30 kg anchor and 58 m rope, in adition to the 50 m chain, for a 0º setting.

Note: Author says he consider CQR, Danforth, Bruce, Britany, etc., "classic" anchors, and Spade, Brake, Bügel, Delta, etc., "high-holding" ones, for which a 30% reduction in weight can be considered.

1.5.- Calculations based on Banjers wind profile and Phil Dunhulty's Nomogram.

I have been doing some preliminary work with this Nomogram, but numbers for Banjers move in the limits of the curves and I am not sure about anchors efficiency index. Not enough trustable information about this indexes, in my opinion, is posted at Dunhulty's web pages. But making efficiency index equal to 40, which seems to be a fair index for high holding power anchors, I arrive to an anchor weight of 22 kg for a 63 knots wind, so not so far away from other methods. But lower efficiency indexes call for heavier anchors. I've written a letter to Dunhulty asking for help. Let's wait.

On 09/02/05 I received this kind e-mail from Phil Dunhulty:

"Dear Guillermo

Thank you for your interest in the anchor efficiency paper

1. The answer to your first question is yes, certainly you may extend the graphics.

2. The different anchor efficiencies are fairly well explained in the paper. See Figure 16 and 17 and 18

These tables cover most of the anchors commonly in use with their respective indices

What more can I tell you.

Regards

Phil Dulhunty"

Figure 17, from Phil's pages:

Type

|

Test Results Efficiency Index (Holding Power to weight ratio)

|

Average

|

Admiralty Pattern

|

5, 7, 14

|

8

|

Bruce

|

16, 11, 9, 24, 22, 17, 25, 39, 30

|

21

|

CQR

|

36, 9, 12, 40, 26, 70, 12

|

30

|

Danforth High Tensile

|

34

|

34

|

Danforth Standard

|

17, 38, 34, 20

|

27

|

Flook

|

45, 55, 27

|

42

|

When I read Phil's article I asumed these data were not good enough to use them in the calculations, I recognize. I thought they were only indicative. I find dispersion of values too big and probably they are not comparable. I think it's risky to say, i.e., that 30 is a mean value for CQR anchors, when dispersion of values goes from 9 to 70 (!). And if we have to asume this kind of enormous variation, How can we asume 34 is a trustable mean value for Danforth High Tensile's?

Well, but using anyhow these data, and assuming for a 45 lbs (21 kg) CQR anchor an efficiency index of 30, we come to the conclusion that it's holding power, as per the nomogram, should be around 500 kg in sand/mud, which is not enough to withstand the Force 11 winds we are working with. We should go for a bigger one or either use some other anchor with a higher efficiency index, but which one is that one? We cannot say it from Phil's table, except for Danforth High Tensile and Flook, so, as I told before, those data are not trustable enough, in my opinion.

Next days I'll try to extend Phil's curves to the zone of what is needed to work with the input data we are considering here, meaning this data for Banjers, and post the result here.

(To be continued)

1.6 What for Hurricane conditions?

We'll now use William's van Dorn's formula, developed for oceanographic vessels in storm conditions, to estimate the forces acting on a ground tackle subject to an anchorage subject to severe wind and sea conditions:

Rode Forde = 0.20* Wind speed^2*Displ^(2/3) (lbs)

Using a 75 knots wind (well into Force 12) and a Banjers' displacement of 13.7 tonnes (30870 lbs), as per hydrostatic curves, we come to an staggering:

Banjers Rode Tension = 6545 lbs (2,97 tonnes or 3026 daN!!!)

This is really a huge tension, much more than that those obtained from Bob Smyth's analisis or the ABYC rules (1920 lbs).

Using Al's calculator for a 11 m boat in 10 m depth, good seabed holding, 1.5 m bow and a ground tackle using a mixed rode of 15 m, 10 mm chain and nylon, to obtain a dinamic overtension (due to wind and waves) of 3026 daN for mixed rodes, we need to introduce in the calculator a wind of 92 knots instead of the 75 considered in Van Dorn's calculations. So, we can realize the difference among both methods. Van Dorn takes into accoun the Displacement and Al's calculator takes Length, which may be the cause of the discrepancy.

With the preceding data, following Al's calculator to handle a 92 knots wind, (Assuming a rode angulation at the anchor of 8º), we need an anchor of 35 kg, as well as 70 m nylon rope in adition to the 15 m chain , to get a 6:1 scope.

Following Van Dorn's tables (From the pages of C&C Yachts):

"...However William van Dorn in "Oceanography and Seamanship"; Dodd, Mead (1974), presents a graph based on calculations for anchoring oceanographic vessels in storm conditions (?). It suggests that the optimum chain/nylon combination for anchoring vessels < 50ft. in 30 ft. of water under storm conditions is a 20% chain, 80% nylon rode with an overall scope of 6:1. Assuming that the boat's bow chock is 6 feet above the water and that the waves are 4 feet (8 feet peak to trough = 2.4 m) this works out to a 240 foot total rode comprised of 48 feet of chain (14.6 m) and 192 feet (58.5 m) of nylon. Clearly these are extreme conditions. In shallower water the rode could be reduced proportionately. However, the length of chain required approximates one boat length and a good working rule for a combined rode is a boat length of chain plus whatever nylon is required to give a 6:1 scope. In shallower water, the scope should be increased, within swing limitations, to 7:1 to permit the bow to lift more easily to the choppy waves near the shore".

Now let's have a look on what a reputable Classification Society states for Yachts and Boats under 24 m length.

From the 2005 edition of their Rules & Guidelines, Pat 3, Special Craft, Section 3, Yatchs & Boats under 24 m, Letter G, Anchoring, Towing and Warping Gear, we calculate the following for Banjers:

Numeral Z = 0.6*L*B*H1 + A = 53.14 m3

Being:

L=(Lh+Lwl)/2 = 10.41m

B = maximum hull breath = 3.48 m

H1 = draft, corrected = 2.3m

A = 0.5* Wheelhouse volume = 3.12 m3 (over deck, roughly)

With this numeral, and a Displacement of 12 tonnes, we enter the different tables and formulas and we obtain (Minimum values for all around sailing):

Main anchor weight: 21 kg (For what they nominate as "high holding power" anchors: Bruce, CQR, Danforth, D'Honne, Heuss, Pool & Kaczireck)

Secondary anchor weight : 18 kg. (You must carry both)

Length of chain line: 32.5 m (round bar steel chain, DIN 766) (for every anchor)

Anchor cable nominal thickness: 8 mm

Towing line length: 50 m

Towing line nominal diameter: 22 mm (3-strand hawser-lay nylon rope, DIN 83330)

Warping ropes: 2 of 15.6 m and 2 of 10.4 m, 18 mm nominal diameter, same rope as before.

In adition, GL states the follwing:

- The weight of Main and Secondary anchors may vary in +/- 7% if the combined weight is no less than the sum of the stipulated weights. (This sum for high holding anchors is, in our case, 39 kg, which approximates the 35 kg obtained before for 92 knots winds, using Al's calculator)

- Both anchors may be on chains or on lines with chain outboard shot.

- Main anchor weight may be reduced 25%, to be used in inland waterways where strong currents and high seas can be excluded, in our case 16 kg. May be substituted by an Stock anchor of 1.33 the weight of the main anchor, in this case 21 kg again.

- The chain may be substituted by 49 m of 22 mm three branded nylon rope plus 6 m of 8 mm outboard shot chain, shackled to the anchor. Rope line must have a spliced-in thimble at one end.

- Anchor chains and chain outboard shots must have reinforced links at the ends.

- A swivel is to be provided between anchor and cable.

- The chain has to be made fast to the boat in a quick release safe operating manner, with fastening strength being no less than 15% but no more than 30%, of the normal breaking load of the chain.

And gives the following caring recommendations for synthetic ropes:

- Stowage below deck once at sea (because of solar radiation)

- Do not stow near heating appliances.

- From time to time inspect them carefully for external and internal defects.

- Replace defective thimbles. Splice-in loose thimbles afresh and seize-in firmly.

My interpretation on this two anchors scheme is that we could use a working tackle with a 18 kg anchor and 49 m of 22 mm 3-strand nylon rope, plus 6 m of 8mm chain, for good weather anchoring, ready to be made fast in line to the main 21 kg anchor with the 32.5 m of 8 mm all chain rode, when strong winds, even up to hurricane forces, are expected. Something to ask Germanischer Lloyd (??).

Both anchors should be fast setting ones.

With the working tackle as said before, we could handle 40 knots winds (The top of a Force 8) in a 10 m depth anchorage, which is good enough for most ocasions. The extra diameter of the nylon rope of the working tackle is needed to be able to withstand the force in a hurricane, when deploying the two anchors, working both on this rope. Well, but I realize we, most of mortals, do not face hurricanes often, so probably we could use a little bit of more chain, let's say 12 m, and a lighter rope, of let's say 16 mm, (much more handable but still with more than enough resistance) for the "normal conditions". When we expect things may deteriorate to really heavy conditions, then we should add the main anchor and substitute the 16 mm rope for a 22 mm one.

To allow for corrosion, etc, I'd go for an all around 10 mm chain, instead of the 8 mm recommended.

2.- What do manufacturers recommend for a 36 feet heavy boat?

Here you have the information from some well known anchor manufacturers. Some of them enter with weight of the boat, rather than length.

Bruce: Storm, 13kg; Working 6.5 kg; Rope: 15 mm; Chain: 9 mm; Minimum chain length: 6.5 m; Anchor shakle: Pin diameter: 10,5 mm, Body diameter: 9 mm.

Bruce: Storm, 13kg; Working 6.5 kg; Rope: 15 mm; Chain: 9 mm; Minimum chain length: 6.5 m; Anchor shakle: Pin diameter: 10,5 mm, Body diameter: 9 mm.  Spade: Model 100, 20 kg (steel). For boats with LOA < 50', Disp < 12 tonnes.

Spade: Model 100, 20 kg (steel). For boats with LOA < 50', Disp < 12 tonnes. CQR: Maximum recommended size (Drop forged): 16 kg / 35 lb

CQR: Maximum recommended size (Drop forged): 16 kg / 35 lb Delta: Maximum recommended size (Galvanized): 16 kg / 35 lb

Delta: Maximum recommended size (Galvanized): 16 kg / 35 lb Danforth (20 knots winds): Standard model, 16 lbs / 7.3 kg; Chain minimum length: 4' (1.22m); Chain diameter: 3/16" ( 5mm aprox)

Danforth (20 knots winds): Standard model, 16 lbs / 7.3 kg; Chain minimum length: 4' (1.22m); Chain diameter: 3/16" ( 5mm aprox) Flook: 10 kg (22 lbs); 3 strand Nylon rode, 13 mm. Shackle size: 12 mm.

Flook: 10 kg (22 lbs); 3 strand Nylon rode, 13 mm. Shackle size: 12 mm. Fortress (30 knots winds): FX 16, 4.5 kg / 10 lbs. Nylon rope, 13 mm; 4 m chain, 8 mm; Shackle, 8 mm.

Fortress (30 knots winds): FX 16, 4.5 kg / 10 lbs. Nylon rope, 13 mm; 4 m chain, 8 mm; Shackle, 8 mm. Max: Max 17 (Pivoting, 50 pounds; Rigid 57 pounds)

Max: Max 17 (Pivoting, 50 pounds; Rigid 57 pounds)  Buegel (Bügel): HS Steel, 24 kg; 10 mm chain (For boats from 10 to 15 tonnes)

Buegel (Bügel): HS Steel, 24 kg; 10 mm chain (For boats from 10 to 15 tonnes) Luke (fisherman): Storm anchor, 72 lbs (35.5 kg) (They recommend 2 lbs per WL foot)

Luke (fisherman): Storm anchor, 72 lbs (35.5 kg) (They recommend 2 lbs per WL foot)

Their commercial sites, some of them with interesting info about anchoring and anchor tests.

Notes:

1.- Some of those recommendations seem to be quite low for serious cruising, from my point of view, as we've seen before.

2.- Interesting to find that Danforth and Fortress, the two anchors more prone not to reset after breaking away on sandy bottoms (as per the tests upper mentioned in this article), are the only ones to advert the wind velocity in their anchor chooser (20 & 30 knots, respectively), just telling you have to be cautious for higher wind velocities.

(02.07.05) MORE ANCHORS IN THE MARKET:

(02.07.05) MORE ANCHORS IN THE MARKET:

(Click on images to access their web sites)

SARCA

|

MANSON SUPREME

|

ROCNA

|

BULWAGGA

|

OCEANE

|

|

|

|

|

|

|

The recommendations from these manufacturers for a Banjer like sized boat are:

Sarca: Sarca Anchor Nº 7, Galvanized (25 kg / 55 lbs). Leader chain, 13 m of 12 mm. Stainless shackle 12 mm.

Manson Supreme: No recommendations available at the web site.

Rocna: Rocna 20 (20 kg / 44lbs / 1174 cm2 blade area) (Size kindly confirmed by Craig Smith, of ROCNA Anchors)

Bulwagga: 44 lb ( 20 kg). Because of length it could be 27 lbs (12.3 kg), but they advertise going one size bigger if the boat is a heavy weight (And Banjers are!)

Oceane: Oceane 16, 16 kg / 35 lbs

Interesting to find that the manufactures of all these "new breed - high holding" anchors, except Oceane's, recommend a weight in the range of of 20-25 kg (44-55 lbs), also in line with Spade's and Buegel's. "Older" plough/claw type anchors like Bruce, Delta, CQR and the like, recommend (see upwards) weights in the range of 16 kg (35 lbs) or less, which seems to be not enough at all. So the "high-tech" guys, who talk about special surfaces, chisel blade tips, balanced weight and the like, finally go for a much more conservative weight recommendation than manufacturers of the less sofisticated anchors (!!!). I like this approach, meaning to me that although a good design is important to the performance of an anchor, weight is also a fundamental parameter not to forget for an all around one.

New kid on the block (Nov 2006)

HydroBubble

This anchor has had very good results in Sail Magazine 2006 Anchors Test, with an extraordinary holding power.

From SAIL magazine: "Quick sets and multiple 5,000 pound pulls at 5:1 scope proved it worked beautifully everytime"

Its setting characteristics are not based in weight (neither total or tip's), but in attaining always the right position because of the floatation bubble.

They reccommend their model Standard 45 for a Banjer like sized boat.

Phil Dunhulty's bottom/anchor table

Approximate Relative Holding power of equal weight anchors in different Types of holding ground

|

Grapnel

|

Admiralty

|

Bruce

|

Plow CQR

|

Danforth

|

Stockless

|

Flook

|

Mud

|

2

|

3

|

7

|

8

|

7

|

6

|

9

|

Sand

|

3

|

5

|

7

|

7

|

8

|

6

|

9

|

Gravel

|

5

|

6

|

7

|

6

|

6

|

6

|

7

|

Clay

|

6

|

6

|

7

|

6

|

5

|

4

|

6

|

Weed

|

7

|

8

|

4

|

4

|

4

|

3

|

5

|

Rock

|

10

|

8

|

2

|

2

|

2

|

1

|

3

|

(Ratings Out Of Ten)

No anchor is designed to hold well in all kind of bottoms.

For serious cruising you should carry two or three types aboard.

3.- My practical suggested method to test your anchor weight and type: 'Bollard Pull' test.

Here you have something interesting to do this season!

As we found before, a Force 11 wind will impose the rode with a force more or less equal to the Bollard Pull of a 27" propeller in a Banjer mounting Perkins 4236, as a rough approximation.

So, you could take your beloved Banjer to a convenient and isolated location, with a 3/5 mts depth firm clay (**), mud or sand bottom , with no boats around, in a calm day. You should look for a bottom as horizontal as possible, with no weed. Don't test in very soft mud or clay, as most anchors don't hold well (Unless your anchor is specifically designed for this job, as the Fortress at 45º), neither in a hard clay, dense sand, weed or gravel/rocky bottoms, as your anchor may not set, penetrate adequately or bending at the flukes.

Firmly dig your main anchor by means of short bursts of power (you may visual check it with the help of a tender in clear waters). Let out 25/35 mts of a 13 mm+ nylon rope plus 10 mm chain (at least one boat length of chain), making it strong to both rear cleats of the Banjer by means of an 'Y' strong rope connection. Slowly open throttle up to 2250 rpm for Perkins 4236 or around 1700 rpm for Perkins 6354 (If you go all the way up with this engine, you'll be exercing a pull in excess of 900 kg, which makes a more demanding test) Then slowly veer the boat 30º to each side. If the anchor holds, or moves but not breaks out, this could be one to take with you for an extended voyage. If it doesn't hold, or fails to reset, you'd better use it only under trustable conditions, as a Lunch Hook or a Working Anchor, depending on its performance.

Finally, test a 180º veer, not under full revs but easing power, gently turning in a wide circle and then slowly opening throttle when the rode is under slight tension again. Watch for the anchor dragging and reset. If it resets and holds to full throttle again, that should be really THE anchor! (For that bottom type)

Try several locations and tests on the same kind of bottom, if possible, to find mean conditions.

I kindly ask members to perform this test with their own Banjers, whenever possible, and let me know the details and results.

(**) Firm clay may be defined as the one on where your thumb will penetrate several inches with moderate effort.

4.- Rode: Chain, Rope, Shackles and the like, from other sources.

Chain

The following are typical maximum working loads for common chain sizes. Working loads are assumed to be at maximum a 25% of breaking load. Numbers are approximate and may vary from different manufacturers. Equivalencies among metric and imperial units are approximate. Numbers in bold highlight what should be the minimum choice for Banjers.

Standard Long Link

Size (in)

|

Size (mm)

|

Working Load (lb)

|

Working Load (kg)

|

Weight lb/ft

|

Weight kg/m

|

1/4"

|

6

|

1250

|

567

|

0.638

|

0.949

|

5/16"

|

8

|

1900

|

862

|

1.006

|

1.497

|

3/8"

|

10

|

2650

|

1202

|

1.456

|

2.167

|

BBB Short Link

Size (in)

|

Size (mm)

|

Working Load (lb)

|

Working Load (kg)

|

Weight lb/ft

|

Weight kg/m

|

1/4"

|

6

|

1250

|

567

|

0.72

|

1.071

|

5/16"

|

8

|

1900

|

862

|

1.108

|

1.649

|

3/8"

|

10

|

2650

|

1202

|

1.639

|

2.439

|

BBB short link or "calibrated" chain is required for use with anchor windlasses with chain gypsies.

It is important to match the chain and gypsy.

Rope

Nylon double braid or 3-strand rope should be the material of choice for anchor rodes. Braid is more susceptible to chafe than 3-strand, but coils better in the anchor locker and resists much higher loads. On the other hand 3-strand stretches more than the double braid and has better chafing-resistance properties. You may also use an 8-strand rope ("square" rope), but although with good chafing-resistance and working load properties, elasticity is poorer than 3-strand..

Numbers in bold highlight again what should be used for Banjers.

DOUBLE BRAID

Size (in)

|

Size (mm)

|

Breaking

Strength (lb)

|

Breaking

Strength (kg)

|

Working (lb)

|

Working (kg)

|

3/8"

|

10

|

4800

|

2086

|

1200

|

544

|

7/16"

|

11

|

6400

|

3084

|

1600

|

726

|

1/2"

|

13

|

8400

|

3810

|

2100

|

953

|

9/16"

|

14

|

11400

|

5171

|

2850

|

1293

|

5/8"

|

16

|

15400

|

6985

|

3850

|

1746

|

3-STRAND

Size (in)

|

Size (mm)

|

Breaking

Strength (lb)

|

Breaking

Strength (kg)

|

Working (lb)

|

Working (kg)

|

3/8"

|

10

|

3850

|

1746

|

965

|

438

|

7/16"

|

11

|

|

|

|

|

1/2"

|

13

|

5265

|

2388

|

1315

|

596

|

9/16"

|

14

|

|

|

|

|

5/8"

|

16

|

9100

|

4128

|

2275

|

1032

|

Shakle, Chain connecting links, Swivels, Anchor connectors, etc.

-  For the shakle, recommendations are to use one size bigger than chain. So, if you go for a 10 mm chain, you should use a 12 mm shackle. Use drop forged, deep galvanized, load rated models. A 3/8" one will have a WL of 1 Ton, while a 7/16" one will go up to 1.5 Tons.

For the shakle, recommendations are to use one size bigger than chain. So, if you go for a 10 mm chain, you should use a 12 mm shackle. Use drop forged, deep galvanized, load rated models. A 3/8" one will have a WL of 1 Ton, while a 7/16" one will go up to 1.5 Tons.

How to do a warp to chain splice: Visit this Bluemoment page

How to do a warp to chain splice: Visit this Bluemoment page

-  You should be careful with chain connecting links as they may be weak. Check their breaking strength. If in doubt, it's easier and simpler to use a proper shakle when gathering lengths of chain is required. Always respect the one size bigger rule. Never use "quick link" type shackles, as they are not designed for this job.

You should be careful with chain connecting links as they may be weak. Check their breaking strength. If in doubt, it's easier and simpler to use a proper shakle when gathering lengths of chain is required. Always respect the one size bigger rule. Never use "quick link" type shackles, as they are not designed for this job.

-  Be careful also with swivels design and breaking load. Get sure they resist as much as the chain, at least. They really do not work properly under high loads, but will take turns out of the chain in most normal situations.

Be careful also with swivels design and breaking load. Get sure they resist as much as the chain, at least. They really do not work properly under high loads, but will take turns out of the chain in most normal situations.

-  The same about stainless steel anchor connectors. They are nice looking and easy the passage of the anchor connection through the bow roller, but they tend to be weak in real life, many times with a breaking load being a fraction of that of the chain. Check it.

The same about stainless steel anchor connectors. They are nice looking and easy the passage of the anchor connection through the bow roller, but they tend to be weak in real life, many times with a breaking load being a fraction of that of the chain. Check it.

Chafing gear

Nylon will chafe, so you'll need to make good chafing gear. You may use a combination of heater hose, head hose, and fire hose about two feet long, as used by Jim Hughes on board his 50' Irish Mist, to protect a pair of snubbers used in between the rode and the boat, to absorb the chafe specially in storm conditions. You shoud never trust, for serious anchoring, a rope rode working on the bow roller. If you have an all chain rode, use 13+ mm 3-strand snubbers secured to the rode by means of a rolling hitch or chain hook, lead them through the fairleads protected by the chafing gear, and make them fast to bollards or strong cleats.

Nylon will chafe, so you'll need to make good chafing gear. You may use a combination of heater hose, head hose, and fire hose about two feet long, as used by Jim Hughes on board his 50' Irish Mist, to protect a pair of snubbers used in between the rode and the boat, to absorb the chafe specially in storm conditions. You shoud never trust, for serious anchoring, a rope rode working on the bow roller. If you have an all chain rode, use 13+ mm 3-strand snubbers secured to the rode by means of a rolling hitch or chain hook, lead them through the fairleads protected by the chafing gear, and make them fast to bollards or strong cleats.Although original Banjer's windlasses are strong stuff, dont let the chain or rope working on them. Again: Use the snubbers. This will also take away the irritating noise of rode's chain against the bowsprit's chain. In fair weather I'd use only one snubber, leaving the use of two for storm conditions (In this case with rolling hitchs, not chain hooks).

5.- Share your knowledge!

5.- Share your knowledge!

Please send me your contribution. I'll gladly post it here. You may do it by e-mailing me or posting it at the Forum where a dedicated thread has been opened.

You may do it in english, dutch, french, german or whatever other language. Thanks in advance.

29.06.05 Contribution from ALAIN POIRAUD, creator of SPADE and OCEANE anchors

In principle, a good anchor must first and foremost hold, and ideally increase its holding power as forces incur heavier loads on the vessel... but in order to hold, an anchor must first deeply penetrate and set in the various types of seafloors. There are two types of setting: static and dynamic.

- Static Setting: Almost always followed by dynamic setting, this setting is typical for cargo ships, where the anchor, from several hundred to several tons of pounds, sinks into the seafloor from its sheer weight alone. No extensive research has been carried out regarding effective setting for these circumstances. In terms of small craft navigation, we can find a similar static setting with the plow anchor, which they don’t manufacture under 15 pounds, simply because anything lighter could not function. Anchors which are not sufficiently heavy may only offer cursory holding in more compact or weedy seafloors, but they might be very effective in soft mud.

- Dynamic Setting: The traction of the rode ought to force the anchor to pierce and bury in the seafloor. Although its own weight may facilitate setting (static), lightweight anchors will also set; it suffices that the anchor tip encounters a sand ripple, or a soft area to pierce, followed by the traction which drives the the anchor into a set position. On compact or weedy seafloors, anchors tend to skim the seafloor for some distance before taking hold. To ensure a speedy setting in virtually all types of seafloors, there are a certain number of physical characteristics to respect: Regardless of the tool, depending on the substance, two parameters ensure good setting: - The proper setting angle and - The highest amount of pressure possible. The optimal setting angle adapted for anchoring is the “wood chisel.”

- Spatula: Plow anchors, once resting on a hard surface, assume a “spatula” angle with respect to the seafloor. Once the tip encounters a softer spot, it embeds by measure of its own weight to its upper apex, thereby assuming the “chisel” angle, which allows the anchor to completely embed. As previously mentioned, on a compact or weedy seafloor, the plow remains in its “spatula” angle, without setting.

- Scraper Angle: Anchors such as the old FOBs, with a bulky hind portion, tend to do a “handstand,” alighting on their flukes. At this point the flukes meet the seafloor almost perpendicularly, raking the surface without setting.

- Chisel Angle: Three principle examples of this are the Bruce anchor, the German “Bügel” anchor and the SPADE. All three approach the seafloor at an angle superior to 90 °, up to 120 °. These anchors have the reputation for rapidly setting in a majority of seafloors.

- Razor Blade Angle: This angle, superior to 150°, is typical of plate or articulating anchors. They necessitate contact with a sand ripple or soft area for their fluketips to pierce the seafloor surface; they then assume the chisel angle and set. On compact or weedy seafloors, these anchors shave the bottom without taking hold.

- Setting Pressure: Pressure is defined as force divided by surface area. Here, we have two variables: force (daN or Lbs) and surface area (mm² or sq inches). The force must be as high as possible and the surface as small as possible to maximize the pressure. A number of anchors have sharpened setting edges, as do the Fortress, FOB THP, the Bügel or the Spade. The distribution of weight in the fluke tip makes sense in anchor design as it facilitates setting. We can see a great disparity amongst fluke ballasting in various anchors: The fluketips of flat anchors and the CQR comprise between 12 and 16 % of the total weight of the anchor, while the ballasted tip of the Delta contains 28% of its total weight. - The... SPADE anchor... 47% of its total weight in its point. We can see that an anchor will tend to set more easily in the seafloor when it launches with the appropriate penetration angle coupled with the maximum pressure on its fluke tip.

03.10.2005 Collaboration from Craig Smyth, of Rocna Anchors

Hello Guillermo,

Given our conversation a few months ago, I thought you may be interested in this diagram we created:

Just a diagram illustrating the relative differences between tip-weight and setting forces. There is a great deal of confusion about the concept of "tip-weight", in part due to some manufacturers who maintain that a large amount of tip-weight is required to properly set an anchor. We feel obliged to point out that while some tip-weight is important, it does not need to be all that high.

You are welcome to use this graphic on your website.

Regards,

Craig Smith

Rocna Anchors

Read also this article from Peter Smiths, the creator of the Rocna anchor:

13.11.06 Contribution from ALAIN POIRAUD, creator of SPADE and OCEANE anchors

Hi Guillermo,

Just for your information, I just discover the following web page made by one distributor of the Spade anchor..

Good reading

Alain

April 18, 2007. New contribution from Craig Smith (Rocna anchors)

Hi Guillermo,

I just took a look over your webpage on Anchoring once more, and thought I could contribute some more material for you.

- The SAIL and Yachting Monthly testing, which I think you are aware of, we host on our website (see "independent reviews"). You may like to link to.

...................

..................

Regards,

Craig

6.- Anchoring Forums & Reports

You can get most interesting user's info about anchors and their performance from real life experience, at these threads from some cruising

Forums:

And also valuable opinions from independent experts-

Reports

7.- For the time being: My own case study:

Now, what do I carry in my own Banjer, good old MARIE? The following:

One 45 lbs (20.4 kg) CQR with 50 m, 10 mm galvanized steel chain, for all around anchoring. I always sleep on this one, after checking for a proper holding and releasing five times the highest tide's depth, even in good weather and shelterd waters. I have not really tested it under strong gale forces, but only under lower gale scale forces (Forces 8-9). I've checked this anchor does not set well in weed bottoms

One 45 lbs (20.4 kg) CQR with 50 m, 10 mm galvanized steel chain, for all around anchoring. I always sleep on this one, after checking for a proper holding and releasing five times the highest tide's depth, even in good weather and shelterd waters. I have not really tested it under strong gale forces, but only under lower gale scale forces (Forces 8-9). I've checked this anchor does not set well in weed bottoms One 45 lbs CQR with 100 m 14 mm rope, as a secondary, stern and back-up anchor.

One 45 lbs CQR with 100 m 14 mm rope, as a secondary, stern and back-up anchor. One 33 lbs (15 kg) Fisherman style anchor, with 12 m galvanized steel 8 mm chain and 40 m, 13 mm double braid nylon rope. I use it as a working anchor for good weather, low depth, day anchoring; either in sand, mud, weed, gravel or rocky bottoms. Not really trustable with Force 6 gusts on sandy bottoms. I extensively use it in Galicia's summer time, as it is easily and quickly brought back aboard by hand only, even if well digged in sand/mud. Very useful with weed, rocks and gravel bottoms, always using the compulsory buoy/retrieval line. But you have to be very careful about not dropping chain/rope -or veering around- over it, as it gets entangled very easily.

One 33 lbs (15 kg) Fisherman style anchor, with 12 m galvanized steel 8 mm chain and 40 m, 13 mm double braid nylon rope. I use it as a working anchor for good weather, low depth, day anchoring; either in sand, mud, weed, gravel or rocky bottoms. Not really trustable with Force 6 gusts on sandy bottoms. I extensively use it in Galicia's summer time, as it is easily and quickly brought back aboard by hand only, even if well digged in sand/mud. Very useful with weed, rocks and gravel bottoms, always using the compulsory buoy/retrieval line. But you have to be very careful about not dropping chain/rope -or veering around- over it, as it gets entangled very easily.

What do I miss, after all this reading and fussing?

Well, today, 23.01.2005, I think I'd need to add 30 m of 14 mm nylon rope to the main ground tackle, to be able to withstand the worst of the winds expected in my area, sailing season and sailing behaviour, let's say if I get caught anchored in a Galician beach summer's night anchorage when a sudden SW front arrives with gusts reaching almost Force 10 (Most unprobable!).

If I were to go globetrotting, then I'd go for a higher holding power, strong anchor and 70 m of 14 mm double braid nylon rope in adition to the 50 m chain. But I still have to do more thinking, perform some testing with my own (and friends') equipment, as well as hearing from fellow BMC members. Then I'll let you know within the next 'Conclusions' point.

8.- Conclusions. What should we use on Banjers?

(To come whenever I arrive to them! With your help I'll do it quicker)

9.- Books

A selection of books on anchoring (Links to some webplaces where to buy them. This is only a facility for BMC members and friends. BMC does not have commercial interests with the linked sites, nor endorses them).

BLISTERING

BLISTERING

I will explain here my experience with my own good old MARIE, and try to give some advices.

A necessary foreword:

Banjers are 30+ years old boats and they have been maintained in a variety of conditions.

Talking to other Banjer owners, I've found 'osmosis' problems ranging from absolutely zero problems to fully blistered hulls.

Banjers do not seem to present more or less hydrolysis problems than any other boat from the same period with a similar level of maintenance.

Don't trust simple readings with moisture meters taken just from the hull's surface. They may mean nothing even if showing a top of the scale reading. If blisters show up, ask for the professional opinion of a highly experienced surveyor.

Don't trust self-proclamed 'experts', but look for good third parties' references.

|

Now let's go into matters, from my own experience with good old MARIE.

"Osmosis is one of the processes by which water is absorbed into the laminate and it can be and is reversed when the vessel is left to dry out on the hard. The word is, however, among the boating fraternity, aided and abetted by the popular yachting press, usually and totally incorrectly used to describe gel coat blistering formed as a result of the chemical and structural break down of the resin matrix as a consequence of water absorption whether this is by true osmosis or not." (Jeffrey N. Casciani-Wood).

Aligned blistering

(image not from a Banjer)

Notice on this hull how the blisters run along a band about one foot below the waterline. Also note how they appear in clusters lower down on the bottom, and that some areas between clusters are not affected. Examples like these prove once and for all that blistering is not merely a function of material, but also a matter of the quality of the layup. On this boat, the areas of blistering are not random but area-specific and directly related to permeability of the laminate due to imperfections. Once again, the skin out mat was found to be poorly saturated. Right photo contrasts the dry mat against the fully wetted out structural laminate.

Blistering in MARIE's hull

As you can see MARIE's blistering occurs under the same pattern considered in the upper information from Marine Surveys' pages. See the blisters aligning about one foot under the sea level. It happens on both sides of the hull. It may reveal inadequate craftmanship at the time of laminating, raher than poor quality of materials. Blistering probably had its origin within the glass layers just after the gelcoat, where mats/rovings were not properly embebbed with resin, leaving voids where water/acid accumulates by chemical reactions and osmotic pressure.

Blisters were of the Type 4 explained at Jeffrey Woods Marine's pages, so being big and relatively flat. I've treated these blisters one by one, rather than peeling off the gelcoat. Damaged laminate was removed to find sound material, and then epoxy filled, sanded and painted. Damaged zone was found to be at most a couple of milimetres depth and there were no apparent bonding problems among glass layers, with internal laminate showing a good aspect. Marie's hull was 31 years old when the repairing work was done. She lies afloat for the whole of the year at sea, with water temperature in the 12 - 17 ºC range, which is a demanding condition for a GRP hull.

New 2005 info:

Measuring MARIE's hull water content with a Tramex Moisture meter, I've found the hull to be completely water saturated. The instrument hit the top of the scale the whole underwater hull around. Water content in GRP hulls is not by itself a problem, except for the added weight to the boat, wich in Banjers is not great deal. The problem arises when this water finds residual products from the laminating process accumulated in defective workmanship's caused voids, so initiating the resin's hydrolysis process and subsecuent blistering if close to the outside surface.

With a closer inspection on Marie's new treated blisters, I've found what seems to be a defective woven roving/mat layers union. Laminating process of Banjers' hulls seems to have been the following:

1.- Gel-coat

2.- Mat 300 gr/sqm

3.- Mat 450 gr/sqm

4.- Woven-roving 520 gr/sqm

5.- Mat, 450 or 620 gr/sqm (?)

6.- Rest of layers.

The bonding between the 520 Roving and the adjacent layers seems to be defective. The cause may be the woven-roving being poorly resin saturated or the next layers being laminated after some time after the first ones cured. Further laminating may have not bond properly to the previous layers. Because MARIE's hull was laminated in 1971, among other 20+ Banjers, I'd rather go for the first explanation: A poorly saturated layer. Another possible explanation could be inadequate control on premise's temperature when the laminating process took place, being it too low or humidity too high, but I'm more convinced by the poor saturation explanation. This defective woven-roving layer is what is causing blistering.

On the good news side, the internal laminate seems to be in quite a good condition, through what can be checked at bottom openings and blisters repairs. I have been advised by my local expert, to peel off the first layers of laminate whenever possible, allow or force the hull to dry properly, and then rebuild the eliminated layers with vinylester resins and glass mats, and apply a final top-coat paint. Something to carefully study and program for when my economies allow to.

May 2008 note:

2006 and 2007 showed no needing for further treatments. Not any other blisters were found.

|

Marina staff "2005 present": Gelcoat pitting damage!